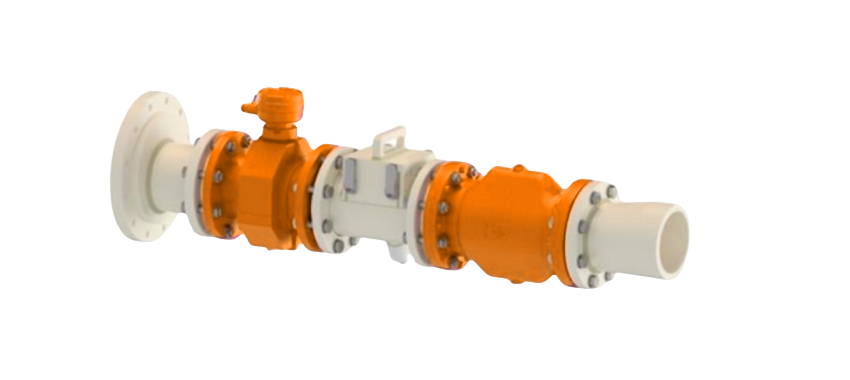

Orifice flow control monitoring equipment (manifold valves)

A system for precise measurement of drainage flow and pneumatic throttling control

Product Introduction

![]()

Overview

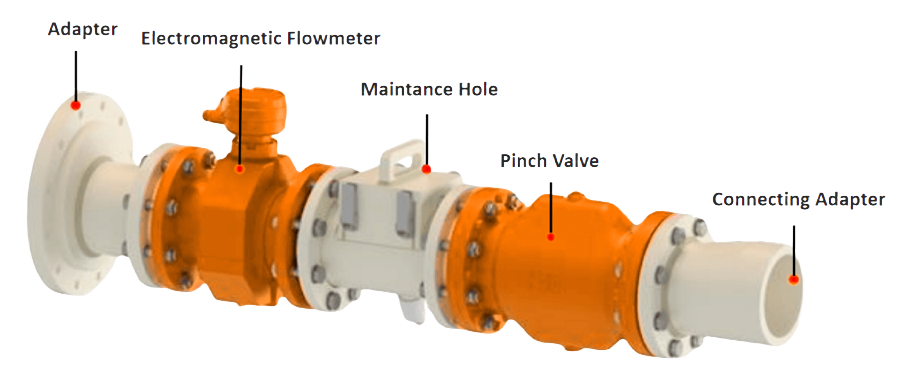

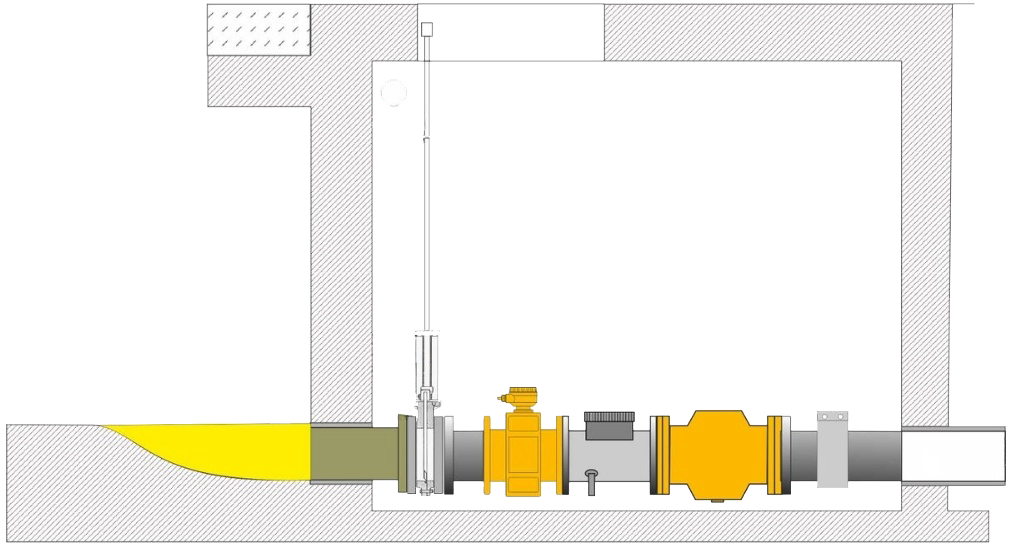

A throttling control system, consisting of an air-driven controller, an electromagnetic flowmeter, a clamp valve, and a level measurement system, is suitable for both full-pipe and non-full-pipe flow measurement. It can be used for precise control of specific flow discharge, i.e., by monitoring the flow rate in real time through the flowmeter, controlling the opening degree of the clamp valve to achieve precise discharge of a specific flow; it can also achieve precise flow measurement, i.e., by controlling the opening degree of the clamp valve to shape non-full-pipe flow into full-pipe flow, and then measuring the flow rate accurately through the electromagnetic flowmeter.

![]()

Application

At the inflow side of rainwater detention tanks and combined sewer overflow (CSO) diversion facilities, the activation of detention space is controlled to regulate the flow into the wastewater treatment plant; at the outflow side of municipal wastewater treatment facilities, it is used to control the flow and accurately bill; and to regulate the flow into the wastewater treatment plant.

![]()

Features

1) The meter is suitable for both full-pipe and non-full-pipe flow measurement, enabling dynamic flow control of the network and integration of precise flow measurement and throttling regulation

2) Automatic throttle control: The flow meter controls the opening degree of the clamp valve to precisely regulate the discharge at a specific flow rate. When the discharge reaches the maximum set value or throttle value, the system automatically switches to flow control mode (the system adjusts outflow based on flow measurement signals), with a deviation within 1%

3) Precise flow measurement: By adjusting the clamp valve's opening degree using liquid level signals, ensuring full-pipe measurements by the flow meter, achieving precise measurements with a maximum deviation from actual values within 2%. Short reset time, no running duration, and precise adjustment are achieved

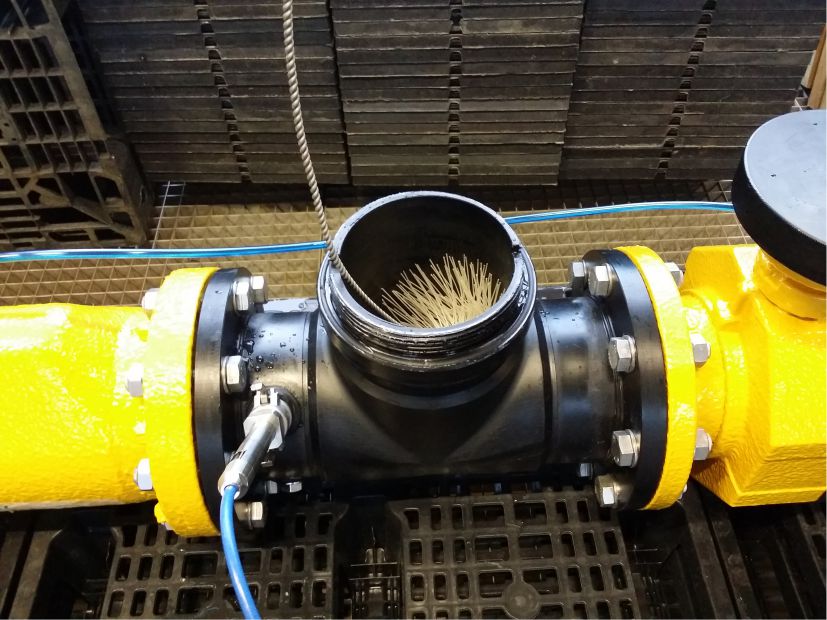

4) Sludge flushing function (self-cleaning): Achieved by adjusting clamp valves to control flows at maximum levels during flushing processes for self-cleaning purposes

5) Power failure protection function: In case of power failure, the system automatically restores clamp valves to open mode

6) Emergency throttling mode (adjustable): During power failures, pressure pads on controllers short-circuit with air compressor pressure containers through regulators; emergency pressure buffer values are set in regulators for such situations

7) Precise and fast response: Pneumatic-based systems utilize continuous pressure regulation without gradation changes; capable of at least 1000 gradation variations for program-controlled operations with minimal deviations

8) Convenient maintenance: Self-cleaning functions reduce manual maintenance requirements significantly while maintaining operational efficiency

9) Safe and environmentally friendly: Utilizes pneumatic drives instead of electric or hydraulic drives in hazardous areas for enhanced safety measures and environmental considerations

![]()

Functions

1) Flow Control: Real-time monitoring of flow rates through a flowmeter, controlling the opening and closing of clamp valves to achieve precise discharge at specific flow rates

2) Precise Flow Measurement: Controlling the opening degree of clamp valves to shape non-full pipe flows into full pipe flows, enabling precise flow measurement using an electromagnetic flowmeter

![]()

Parameters

| Flow Measurement | Electromagnetic Flowmeter |

| Liquid Level Measurement | Pressure-based Liquid Level Meter/Ultrasonic Liquid Level Meter (optional) |

| Measurement Range | 0.2 - 5000 L/s (Depending on the rated size of the system) |

| Minimum Adjustable Flow | 0.2 L/s |

| Nominal Diameter | DN200– DN1500 |

| Explosion-proof Rating | ATEX Zone I |

| Protection | IP68 |

| Compressed Air | Automatic Drain Compressor |

| Power Supply | Maximum 13A,(230±10)VAC |

| Input Signal | 4–20 mA Analog signals (target control values) |

| Output Signal | 4-20 mA Analog signals (instantaneous flow rate, setpoint control value) |

| Communication | RS485(M-bus RTU)/ RS232 /Ethernet /4G |

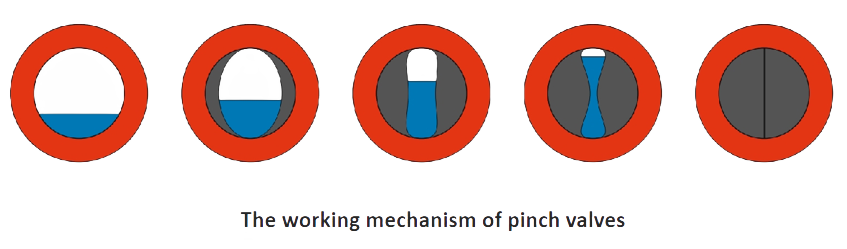

| Control valves | Pinch Valve |

-

Contact UsTelphone:025-86618785 (9:00 -18:00)E-mail:contact@delta.org.cn

-

Official official account

-

Company websiteHead office: Jiangsu Yangtze River Delta Smart Water Research Institute Co., LTDHolding subsidiary:Easten Water AffairsWesten Water AffairsResearch center: Institute of Urban Water Affairs and Water Conservancy, Nanjing University of Information Science and Technology

All rights reserved. All rights reserved