Partially Filled Electromagnetic Flow Meter

Product Introduction

![]()

Overview

DWI has developed a proprietary device specifically designed for the precise measurement of non-full pipe flow. Like conventional electromagnetic flowmeters, it uses Faraday's electromagnetic induction law to measure flow. By using a unique electrode arrangement and non-contact capacitive liquid level measurement, it achieves the simultaneous measurement of liquid level and flow velocity in non-full pipe conditions without the need for additional liquid level measurement devices.

![]()

Application

It is particularly suitable for the precise measurement of non-full pipe flow in the water and wastewater industries, and can be used in measurement sites such as municipal rainwater, sewage, wastewater discharge, and irrigation water pipelines. It is typically used for the measurement and monitoring of flow in closed pipes in municipal sewage, industrial wastewater, urban drainage pipes, and factory outlets.

![]()

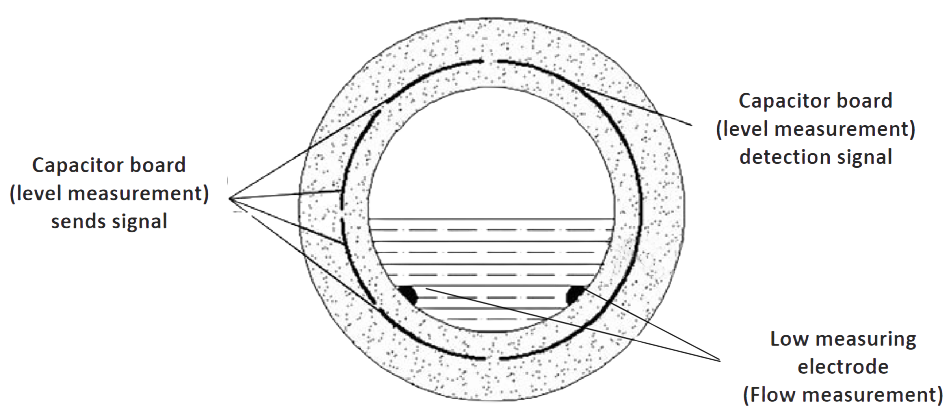

Working Principle

It is an electromagnetic flowmeter that integrates a capacitive liquid level measurement system and is designed for non-full pipe flow measurement. It measures flow velocity based on the principle of electromagnetic induction. The measurement electrodes are located at the lower part of the measurement tube (at 10% of the pipe diameter above the pipe bottom), and the flow can be reliably measured when the pipe filling degree exceeds 10%.

![]()

Features

1) The flowmeter integrates a non-contact capacitive liquid level measurement system (without the need for additional liquid level measurement devices) and can accurately measure liquid levels even in non-full pipe conditions, within a measurement range of 10% to 100% of the pipe diameter

2) The liquid level sensor is integrated within the liner and does not come into contact with the medium, thus it remains unaffected by medium contamination or interference

3) It is particularly suitable for precise measurements of non-full pipe flow in water/wastewater applications

4) It covers a wide range of pipe diameters, with a maximum capacity reaching DN1500

5) A low-position electrode effectively prevents contamination from substances such as oil and grease on the water surface

6) Each set of equipment undergoes calibration in a standard hydraulic laboratory

7) It offers high protection with an IP68 rating

![]()

Parameters

| Measure principle | Faraday principle of electromagnetic induction |

| pipe diameter | DN200~DN1500 |

| Minimum measurable liquid level | 10% inner diameter |

| Velocity measurement range | (0.5~10)m/s |

| Accuracy | Full filled pipe flow: ≤1%Rd; partially filled pipe flow: ≤1%Fs |

| Working temperature | (-25~200)°C |

| Medium requirement | Electrical conductivity ≥50μs/cm |

| Measuring pipe material | 304 stainless steel |

| Lining material | Neoprene/PTFE/F46 |

| Measuring electrode | 316L/Hastelloy B/Hastelloy C |

| Flange material | Carbon steel/Stainless steel |

| Connection | Flange |

| Protection | IP65/IP67/IP68 (Optional) |

| Power supply | 220VAC / 24VDC |

| Output signal | (4-20) mA/ frequency/pulse |

| Communication | HART communication /Modbus protocol /Profibus protocol |

-

Contact UsTelphone:025-86618785 (9:00 -18:00)E-mail:contact@delta.org.cn

-

Official official account

-

Company websiteHead office: Jiangsu Yangtze River Delta Smart Water Research Institute Co., LTDHolding subsidiary:Easten Water AffairsWesten Water AffairsResearch center: Institute of Urban Water Affairs and Water Conservancy, Nanjing University of Information Science and Technology

All rights reserved. All rights reserved